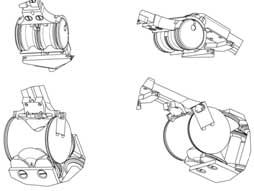

The DLR Hand-Arm System is a robotic system mimicking the kinematic, dynamic and force properties of the human arm using modern mechatronic technologies. What\x92s more, it should allow us to make a next major step towards autonomy in service robotics. It is based on a variable stiffness drive concept with joint structures as close to the biological counterpart as possible.

The DLR Hand-Arm System is a robotic system mimicking the kinematic, dynamic and force properties of the human arm using modern mechatronic technologies. What\x92s more, it should allow us to make a next major step towards autonomy in service robotics. It is based on a variable stiffness drive concept with joint structures as close to the biological counterpart as possible.

The system is designed as a fully integrated hand- arm system that no longer allows the isolated use of the hand or arm, as was the case with the previous modular hands.

Nevertheless it still can be logically divided into a forearm and hand, including the wrist, on one side, and the arm consisting of a 3-DoF shoulder and a 2-DoF elbow, on the other. The requirements of the hand and arm are quite different. For example, vibration damping is of no relevance for the fingers (finger dynamics are negligible in relation to the applied forces), whereas a good vibration damping performance of the arm, especially in the shoulder, is crucial for the whole hand-arm system. Therefore the design aspects have been separately analysed for both systems.

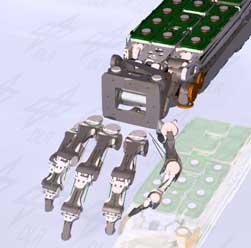

Anthropomorphic Hand

In the design of an anthropomorphic hand, we closely coupled the properties of the human hand rather than its intrinsic structure. The solutions found in biology must be transferred to technical components and evaluated before they can actually be used.

The human hand consists of a palm with metacarpal bones and finger bones. The index, middle and ring finger are similar in their structure and configuration, whereas the thumb and little finger differ considerably; the latter has a bone structure similar to the middle fingers, but its tendons, ligaments and muscles resemble those of the thumb. Furthermore, a thorough understanding of the hand\x92s joints is imperative for realising an anthropomorphic hand, since joints found in biology are radically different from technical joints.

The human hand mainly uses three kinds of joints, which can be divided into 1-DoF and 2-DoF joints. The 1-DoF joints in the hand all are hinge joints; 2-DoF joints can be divided into two types. The metacarpal (second down) joint of the thumb is a saddle joint but with non-orthonormal axes and has been described geometrically by Kuczynski by the saddle of a scoliotic horse. In contrast, the metacarpal (3rd down) joints of the fingers are condyloid. The main difference between saddle and condyloid joints is that condyloid joints have (roughly) intersecting axes, which saddle joints do not have. For the thumb, the axes of the metacarpal are non-orthogonal screws.

The human hand mainly uses three kinds of joints, which can be divided into 1-DoF and 2-DoF joints. The 1-DoF joints in the hand all are hinge joints; 2-DoF joints can be divided into two types. The metacarpal (second down) joint of the thumb is a saddle joint but with non-orthonormal axes and has been described geometrically by Kuczynski by the saddle of a scoliotic horse. In contrast, the metacarpal (3rd down) joints of the fingers are condyloid. The main difference between saddle and condyloid joints is that condyloid joints have (roughly) intersecting axes, which saddle joints do not have. For the thumb, the axes of the metacarpal are non-orthogonal screws.

The thumb can be assumed to be the most important part of the human hand. This is most obvious in hand surgery: a lost finger can be coped with, but a lost thumb is generally solved by pollicisation (replacement of a missing thumb by finger or toe) of, e.g., the index finger or a toe.

Since the coupling of the bones in the human hand is not stiff, compliant motion in almost every direction is possible. Subsequently, there are several opinions how many degrees of freedom the metacarpal and thus the first interphalangeal joint of the thumb has. Kapandji hypothesises two degrees of freedom in the metacarpal and 2 in the first interphalangeal joint, while Benninghoff suggests three DoF in the metacarpal and one in the first interphalangeal joint. Following Kapandji, we consider the metacarpal of the thumb is a 2-DoF saddle joint. The interphalangeal joints of the thumb are similar to those of the fingers. Kapandji proposes that the fifth DoF of the thumb is located in the proximal interphalangeal joint as a limited range DoF along the longitudinal axis of the medial phalanx. One hint to prove this is that the proximal interphalangeal joint of the thumb is not a hinge joint but a condyloid joint. Based on the experiences from pollicisation, this degree of freedom can be assumed less important; after all, near-perfect hand functionality can be regained by replanting the index finger as a thumb.

Putting it Together: The Design of DLR\x92s Anthropomorphic Hand

The condyloid joints of the human fingers imply an additional movement of the finger in the longitudinal direction, since the ellipsoidal contact surfaces cannot be generated using a 2-DoF motion and a common geriatrix. First, this leads to complications calculating the inverse kinematics of the finger. Furthermore, extended wear is to be expected at the contact surfaces. For these reasons, hyperboloid joints are more applicable. Simulations showed that the use of non-intersecting axes of hyperboloid joints reduces the functionality of the hand only marginally, if the main axis of the finger (flexion/extension) is distal to the secondary axis of the finger (adduction/abduction).

The condyloid joints of the human fingers imply an additional movement of the finger in the longitudinal direction, since the ellipsoidal contact surfaces cannot be generated using a 2-DoF motion and a common geriatrix. First, this leads to complications calculating the inverse kinematics of the finger. Furthermore, extended wear is to be expected at the contact surfaces. For these reasons, hyperboloid joints are more applicable. Simulations showed that the use of non-intersecting axes of hyperboloid joints reduces the functionality of the hand only marginally, if the main axis of the finger (flexion/extension) is distal to the secondary axis of the finger (adduction/abduction).

The structure of the finger is designed as an endoskeleton with bionic joints. The metacarpal joint is designed as a hyperboloidally shaped saddle joint, whereas the interphalangeal finger joints are designed as hinge joints. The proximal interphalangeal joint of the thumb is, in contrast to biology, also designed as a hinge joint. This circumvents the negative side effects of technical condyloid joints, while leaving out the thumb\x92s fifth degree of freedom is not problematic. The kinematics of the new hand is closely adapted to the human hand. So every finger differs in \x93bone\x94-length, size and kinematics. For example, the fifth finger PIP joint has to have an inclination of about 15\xB0 to enable opposition to the thumb, while the index and middle finger only have minimal inclination. All joints enable dislocation of the \x93bones\x94 without damage in case of overload, using the elasticity in the drive train.

The structure of the finger is designed as an endoskeleton with bionic joints. The metacarpal joint is designed as a hyperboloidally shaped saddle joint, whereas the interphalangeal finger joints are designed as hinge joints. The proximal interphalangeal joint of the thumb is, in contrast to biology, also designed as a hinge joint. This circumvents the negative side effects of technical condyloid joints, while leaving out the thumb\x92s fifth degree of freedom is not problematic. The kinematics of the new hand is closely adapted to the human hand. So every finger differs in \x93bone\x94-length, size and kinematics. For example, the fifth finger PIP joint has to have an inclination of about 15\xB0 to enable opposition to the thumb, while the index and middle finger only have minimal inclination. All joints enable dislocation of the \x93bones\x94 without damage in case of overload, using the elasticity in the drive train.

In addition to the known assets, such as robustness and short-term energy storage, the use of antagonistic actuation enables us to cope with geometric inaccuracy which is one of the major problems of known tendon-driven mechanisms. In contrast to standard tendon routed systems with inherent constant tendon length, unaligned pulley-axes and other geometrical errors do not overstretch or slacken the tendons, since these are inaccuracies compensated by the elastic elements in the drive train. Therefore no tendon tensioner is needed.

The full system had been completed within SENSOPAC. A video can be found here.